Submitted by egaadmin on

Volume:

67

Number:

3

Page:

Search Text:

FALL 2023

It is the cost of doing business. As a business owner, how often do you hear that said? It seems as if that phrase is always just hanging out there, as a constant reminder that running a business is not cheap. It’s not that business owners are naïve in understanding that there are costs in business, it’s just that those costs are never ceasing, and constantly on the rise. This can cause the owner to feel frustrated and question whether it is truly worth running a business.

When I talk with my members about issues such as regulations, insurance, safety, labor, and production I can feel their frustration as they try to figure out how to comply with these issues and their associated costs. They know that it is a never-ending cycle of compliance just to keep the business in operation. And, just when they think they have it all under control and are in compliance, they are hit with new regulations or cost increases that send them down the road of frustration once again.

So, what are some of the cost driving issues that business owners across the country are facing as we move into the 2024 year? Compliance with governmental regulations is always at the forefront of any discussion. In addition to current regulations there are always impending regulations that are looming just over the horizon.

One of those impending regulations that could have a major impact on production is the OSHA regulation on Heat Injury and Illness Prevention in Outdoor and Indoor Work Settings. This ruling, which is currently in the review stage, outlines how to keep workers safe from heat injury and illness. Once passed, the new rule will mandate for employers the procedures that will need to be followed during times of heat related weather events. This ruling is aimed at keeping employees safe, and rightfully so, as according to the Bureau of Labor and Statics there have been 999 deaths attributed to heat from 1992-2021.

In the granite industry, silica exposure is always a cause for concern as it can lead to an incurable disease called Silicosis. OSHA already has regulations geared at controlling silica exposure in the workforce, which employers are required to follow. Now it appears that the Mine Safety and Health Administration, (MSHA), is preparing to adopt the ruling used by OSHA, for use in the granite quarries. The adoption of this rule will be challenging for quarry operators trying to stay in compliance of silica exposure.

In addition to compliance with regulations, there is also the ever-increasing costs associated with insurance and protecting your business. The Commercial Property/Casualty Market Index study for 2023 found that Q2 2023 was the 23rd consecutive quarter of premium increases, at 8.9%. With commercial property having the highest reported increase at 18.3%. Similarly, the cost for offering health care to employees has risen 7%, according to a U.S. News & World Report, dated October 18, 2023. The average annual cost for employee health care is $8,435 for single coverage and $23,968 for family coverage.

When you add in rising costs for labor, materials, and equipment, it becomes apparent why running a business becomes so frustrating, and why the price for goods and services keeps going up. The cost of doing business today is higher than it was yesterday, and it certainly will be higher tomorrow.

Prepare for tomorrow.

RONNIE BROWN RETIRES FROM MILES SUPPLY OF ELBERTON

AFTER TWENTY-FIVE YEARS OF EXCELLENCE!

Ronnie Brown began his career with MILES SUPPLY OF ELBERTON in 1998. He brought with him roughly 36 years of experience with sales in the granite industry. After an amazing twenty-five years with Miles, Ronnie decided to retire. Ronnie’s career has taken him through many highs and lows, management changes and ownership changes. He was steadfast through new product and machinery along with building construction, expansion, and new technology. He has traveled more than he would have ever been able to do and has seen almost the entire country in his position.

When Ronnie began work at Miles Supply of Elberton, they were working with limited product options. One of Ronnie’s first tasks was to begin to build the list of products that would be sold. This proved to be a huge success as everything sold immediately and the warehouse had to be restocked the following month. Ronnie played an intricate role in the functions and capabilities of the exclusive Sand Handler.

Slipping into a relaxing and slow-paced retirement, however, is not among any of Ronnie’s plans for this next chapter of his life. Ronnie intends to travel. He intends to visit Bowling Green, Kentucky where Corvettes are made and Bristol, Tennessee to Bristol Motor Speedway. One of Ronnie’s favorite things in this world is drag racing. There will be time in his retirement set apart for this fun. And of course, time will be set apart for his family. The granite industry is grateful for the time Ronnie spent becoming an intricate part its betterment.

Elberton Granite Association Awards

2023 Scholarships To Local Graduates Ryleigh Rosenburg is a 2023 graduate of Elbert County Comprehensive High School. Ryleigh graduated with honors with distinction and was recognized at the 2022-23 Awards Night for demonstrating academic excellence during her four years at ECCHS. She was also selected as a Senior Superlative for the Class of 2023.

She is connected to the granite industry by her own doing. She has been employed by A.Q. STONE DESIGN COMPANY since the summer of 2021. She began working with them through the ECCHS Work-Based Learning Program. Ryleigh intends to go to Georgia College and State University where she will study physical therapy. Her future goals are to work in a medical office providing physical therapy to those that need it. Gavino Marnell graduated with the 2023 Class of Oglethorpe High School. This enthusiastic young man is the son of Erik Marnell. Erik is Regional Sales Manager with MATTHEWS GRANITE. He has worked with Matthews for eleven years starting his career with them in 2012.

Gavino is attending Athens Tech and is studying to receive an associates in culinary arts. His dream is to work as a pastry chef for Disney. The granite industry wishes him the best of luck on his accomplishing his goals! Isabella Cone is a 2023 graduate of Elbert County Comprehensive High School. Isabella graduated with honors with distinction. During her time in ECCHS she participated in the Work Base Learning Program where she worked with a local small business. Isabella is the daughter of Stewart Cone, who is a long-time salesperson at EAGLE GRANITE, a division of MATTHEWS GRANITE. Isabella’s grandfather, Hudson Cone, retired from Elberton Granite Association where he was employed for 32 years as the Promotions Director and Associate Editor.

Isabella will be attending Georgia College and State University where she will work towards a bachelor’s degree in psychology. She hopes to work toward a double major with English as well. Once Isabella reaches her goal she hopes to work as a psychologist.

Third Generation Joins Quality Monument Sales

Grandchildren, Branson & Marlena Newest Additions

Voting Member Firm, QUALITY MONUMENT SALES, INC. has always run their business with strong family ties. Those ties continue to grow as grandson, Branson Bonds and granddaughter, Marlena Rhodes join the team.

Branson is sixteen years old and a Junior in school. He is extremely active in sports but has learned how to divide his time to include school, sports and work. He takes part in Elbert County Comprehensive High School’s Workbase Learning Program like his uncle, Jonathan did when he was in high school. This program includes Branson’s work position into his curriculum and school schedule allowing him the opportunity to learn more skills of the trade before he is faced with adulthood. At Quality Monument Sales, Branson is learning an array of skills from office tasks such as taking orders to learning stone cutting in the production department. He intends to attend college once he graduates high school. He will focus on business before returning to Quality Monuments.

Marlena Rhodes has also joined the family business. Marlena focuses on office tasks such as answering phones, taking orders and filing. She began working part time for Quality around the beginning of 2022. Marlena hopes to expand her skills with the business and grow with the company. Currently, Marlena splits her time between Quality and another part time job so that her skills can become more versatile. Wilson Industrial Electric Builds Two Gantry Saws

WILSON INDUSTRIAL ELECTRIC fabricated two outdoor 5’ 4” Gantry Saws for a customer in Pennsylvania. The machines were made with a 30-horsepower motor. They can hold 64” blades making their cutting depth 27”. As shown in the photo below, blocks can be lined up and programmed for the saw to cut one after another expediting production by hours compared to having to program one block at a time.

Travco Metal Works Expands Market with New Machines

TRAVCO METAL WORKS rethought the design for his automatic top polisher and automatic patch polisher to accommodate smaller spaces and purposes. These two machines were developed for a retail customer in Scottsburg, Indiana. The automatic top polisher shown on the left is built with a 5-horse power motor while the automatic patch polisher on the right is built with a 15-horsepower motor. Each machine has touchscreen programming along with a hand-held remote control to support more efficient programming and employee safety. The machines automatically change their heads as needed and can be programmed to service up to 100 stones at a time.

These machines are perfect to minimize scrap piles allowing stones that have been finished with an error to be refinished, re-purposed and added back to inventory. This maximizes needed space in facility lots along with maximizing inventory of quality stones. Henry & Henry Updates Their Freight Capabilities

Many industries depend on trucking companies to deliver their product throughout the United States. The granite industry is no exception to this. It relies on companies like HENRY & HENRY, INC. to deliver the monuments that are so meticulously crafted to its customers. Henry & Henry can always be trusted to deliver their loads with the best of care. For this reason, trucking companies must stay up to date with trustworthy tractor trailers. Henry & Henry recently invested in completely rebuilding their 2005 Peterbilt 379X tractor trailer from the engine all the way to the carpeting. A 550 Horsepower Cat engine was installed along with a new 18 speed transmission. Inside the cab the driver has a rebuilt 70-inch stand up sleeper for the long-haul trips. Along with the rebuilt semi-truck, Henry & Henry also purchased two new Reitnouer 48-foot trailers to carry the product needed. The trailers are engineered for long life and a rock-solid design to get the loads where they are designated to go. “This truck is expected to travel every route that Henry & Henry runs across the United States.” - Dennie Martin, Driver. Granite Finishes - What Options Do You Have?

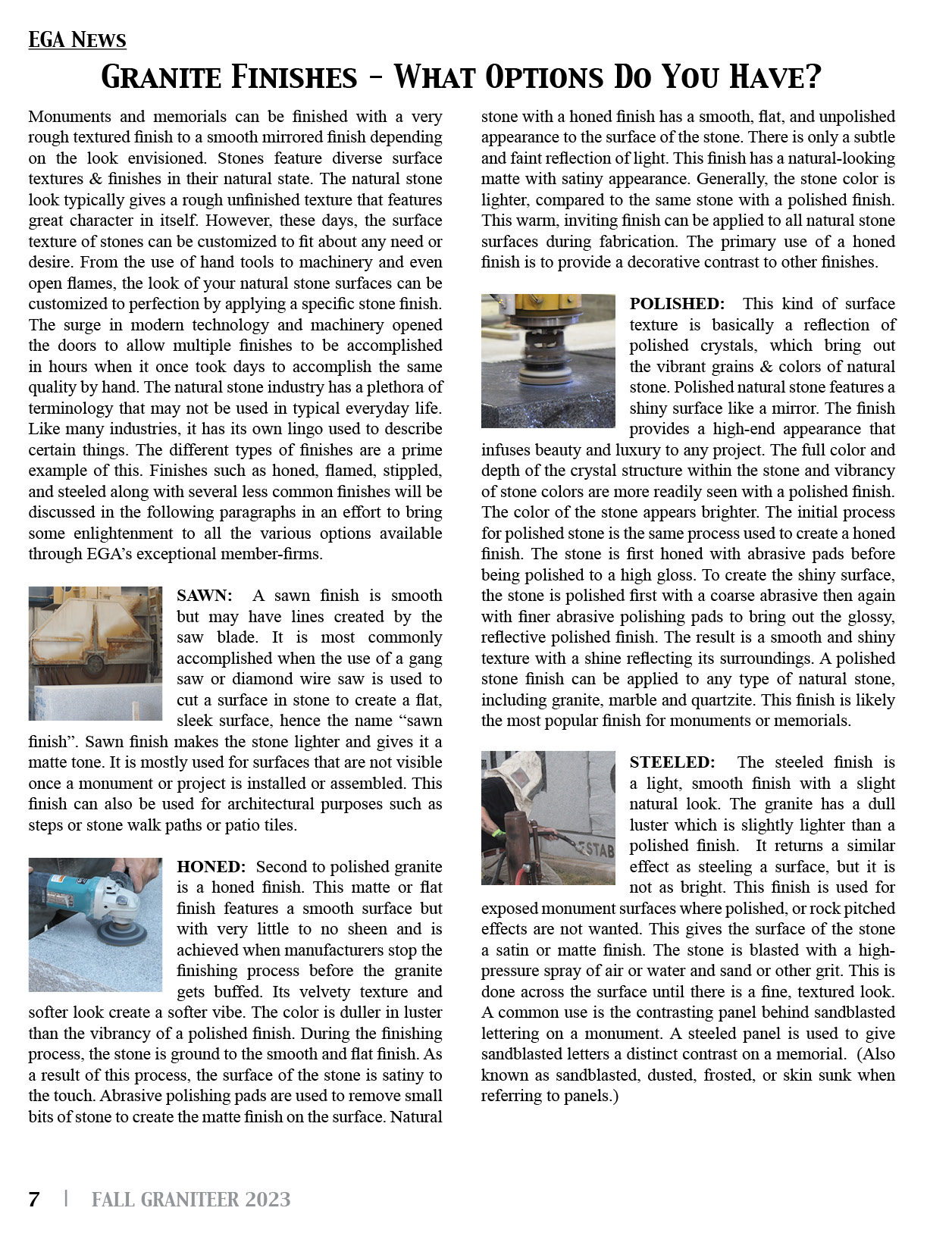

Monuments and memorials can be finished with a very rough textured finish to a smooth mirrored finish depending on the look envisioned. Stones feature diverse surface textures & finishes in their natural state. The natural stone look typically gives a rough unfinished texture that features great character in itself. However, these days, the surface texture of stones can be customized to fit about any need or desire. From the use of hand tools to machinery and even open flames, the look of your natural stone surfaces can be customized to perfection by applying a specific stone finish. The surge in modern technology and machinery opened the doors to allow multiple finishes to be accomplished in hours when it once took days to accomplish the same quality by hand. The natural stone industry has a plethora of terminology that may not be used in typical everyday life. Like many industries, it has its own lingo used to describe certain things. The different types of finishes are a prime example of this. Finishes such as honed, flamed, stippled, and steeled along with several less common finishes will be discussed in the following paragraphs in an effort to bring some enlightenment to all the various options available through EGA’s exceptional member-firms.

SAWN: A sawn finish is smooth but may have lines created by the saw blade. It is most commonly accomplished when the use of a gang saw or diamond wire saw is used to cut a surface in stone to create a flat, sleek surface, hence the name “sawn finish”. Sawn finish makes the stone lighter and gives it a matte tone. It is mostly used for surfaces that are not visible once a monument or project is installed or assembled. This finish can also be used for architectural purposes such as steps or stone walk paths or patio tiles.

HONED: Second to polished granite is a honed finish. This matte or flat finish features a smooth surface but with very little to no sheen and is achieved when manufacturers stop the finishing process before the granite gets buffed. Its velvety texture and softer look create a softer vibe. The color is duller in luster than the vibrancy of a polished finish. During the finishing process, the stone is ground to the smooth and flat finish. As a result of this process, the surface of the stone is satiny to the touch. Abrasive polishing pads are used to remove small bits of stone to create the matte finish on the surface. Natural stone with a honed finish has a smooth, flat, and unpolished appearance to the surface of the stone. There is only a subtle and faint reflection of light. This finish has a natural-looking matte with satiny appearance. Generally, the stone color is lighter, compared to the same stone with a polished finish. This warm, inviting finish can be applied to all natural stone surfaces during fabrication. The primary use of a honed finish is to provide a decorative contrast to other finishes.

POLISHED: This kind of surface texture is basically a reflection of polished crystals, which bring out the vibrant grains & colors of natural stone. Polished natural stone features a shiny surface like a mirror. The finish provides a high-end appearance that infuses beauty and luxury to any project. The full color and depth of the crystal structure within the stone and vibrancy of stone colors are more readily seen with a polished finish. The color of the stone appears brighter. The initial process for polished stone is the same process used to create a honed finish. The stone is first honed with abrasive pads before being polished to a high gloss. To create the shiny surface, the stone is polished first with a coarse abrasive then again with finer abrasive polishing pads to bring out the glossy, reflective polished finish. The result is a smooth and shiny texture with a shine reflecting its surroundings. A polished stone finish can be applied to any type of natural stone, including granite, marble and quartzite. This finish is likely the most popular finish for monuments or memorials.

STEELED: The steeled finish is a light, smooth finish with a slight natural look. The granite has a dull luster which is slightly lighter than a polished finish. It returns a similar effect as steeling a surface, but it is not as bright. This finish is used for exposed monument surfaces where polished, or rock pitched effects are not wanted. This gives the surface of the stone a satin or matte finish. The stone is blasted with a high-pressure spray of air or water and sand or other grit. This is done across the surface until there is a fine, textured look. A common use is the contrasting panel behind sandblasted lettering on a monument. A steeled panel is used to give sandblasted letters a distinct contrast on a memorial. (Also known as sandblasted, dusted, frosted, or skin sunk when referring to panels.)

FLAMED: The thermal texture is a rough, random texture finish with a heavy pocked surface. This technique uses an oxygen and propane mixed torch, similar to what welders’ use. This kind of rough surface is obtained by bursting crystals during the process of heating the stone. This process, as the name indicates, involves using a hot torch flame and running it over the surface of the stone to create a textured, non-slip finish that has a semi-rough surface. The wet edge of the stone is touched with the torch, sending chips flying and leaving the edge a bit rough, yet straight – creating a sandy paper-like texture. Thermal texture is widely used on granite steps to prevent slipping that would normally occur with a polished or steeled finish. The effects of this finish can vary from one natural stone to another. (Also known as thermal finish.)

ROCK PITCH: Rock pitched finishes are rough rock surfaces that have been pitched by hand using a rock hammer or pitching tool and chisel. Experts chip away at the face of the stone to produce a rugged-yet-crafted, natural appearance. This finish offers a rustic finish that maintains the natural rock texture of the stone. The end result enhances the natural beauty of the stone by highlighting its intricacies and giving it a rough appearance. This finish is most often used on the sides or tops of a memorial or base of a monument along with projects such as architectural steps, coping or even wall blocks. It is the preferred finish for bases set in cemeteries as it is the most forgiving finish for lawn maintenance.

In some situations, a monument may warrant the use of a specialty finish. Some of the less common finishes of stone include the leathered finish, also referred to as antiqued finish or brush finish, dusted or sandblasted finish along with bush hammered and flamed or thermal finish.

LEATHERED: This finish is more commonly used in counter tops or dimension stone where a good amount of traffic will be passing through - especially outdoor applications where weather can cause slippery footing. A leathered finish, also known as “antiqued”, begins with a honed finish that is then treated by running a diamond-tipped brush over the surface. This process is highly customizable, resulting in a more- or less-polished look depending on how many times the brushes stroke the surface. This technique gives the stone a weathered, rustic look. A leathered stone finish can be applied to marble, granite and quartzite stone surfaces. (Also referred to as antiqued or brush finish.)

BUSH HAMMERED: Bush hammering is an action which leads to a textured surface. This look is accomplished using a masonry tool that resembles a meat tenderizer. The surface of the stone is hammered with this tool until it breaks up the surface enough that deep pockets and ridges are made, resembling a natural rough texture. This finish creates a great contrast to some of the more common finishes. It is a great method to use for accents in the stone such as borders or edges.

STIPPLED: A stippled surface appears to have small “dimples” caused by stunning the surface with a small, pointed tool. This type of finish provides a great slip resistant benefit for areas requiring added safety for foot traffic. It can be found being used as the finish for the top of tiles to ensure walk-paths have a good texture for safe footing. It can also be found as accent textures on monuments and memorials.

SHELL ROCK: This finish is most often used to picture frame the face of the memorial. True shell rock pitch produces pronounced deep scallops across interior surface of a stone where the stone would typically be flat. This finish most closely resembles the natural finish of a boulder.

HAND AXE: Lighter and brighter than a traditional frosted finish. Achieved by chiseling. Most commonly used when crafting Square Raised Lettering and/or Bias Relief Sculpturing.

In conclusion, the many methods of finishing a surface of stone ensures that whatever the combination of finishes used, a one-of-a-kind work of art is an ever-present possibility. These finishes are achieved through expert craftsmen and the use of various types of highly specialized machinery and/or chiseling and stone cutting tools.

Versatility & Function Of Granite

Since prehistoric days, men and women have found use in natural stone such as granite for a multitude of functions. The earliest known works of representational art and communication are stone carvings of pictures on cave walls. This was done usually to tell a story or document information.

Carving stone into sculpture is an activity older than civilization itself. Prehistoric sculptures often were human forms but progressed into animal forms and abstract. They could be found in open fields, ceremonial land, caves and common areas. Relief sculptures were found on cave walls as memorials to honor a loved one and pieces of art to enjoy.

Granite has passed the test of time in the vast ways that it can it be utilized. It has always proven to be a strong substance that will hold for the duration of its needed purpose. The beauty of natural stone combined with expert craftsmanship and design can produce a unique and lasting result. In today’s culture, it continues to be used to honor a loved one’s memory in the form of a cemetery monument, a mausoleum or a public monument or sculpture. Granite holds a unique diversity in the different forms it can take.

For thousands of years, it has been used as construction material. Beautiful buildings and architecture can be found all over the world with granite as its main focus. Blocks can be stacked and bonded together to build retaining walls, bridges and even the exterior and interior walls and foundations of a building. Indoors, granite can be cut and polished to form counter tops, shower stalls, tiles. It can be used to make tiles for flooring and dimensional cuts for fireplaces. Granite is a prestige material used in homes and used in projects to produce impressions of elegance and quality.

Road and park departments use granite for many purposes also. It can be cut into curbing, crushed into gravel. Granite pavers make an interesting way to establish a driveway, pave a small city street or create a park patio. Even the world of sports uses granite. The sport of curling is centered around a granite rock polished and shaped weighing between 38 and 44 pounds to create the curling stone. The polish must be smooth enough to glide across ice. Yes, granite proves to be timeless in its many uses and function. The men and women that create the EGA family have learned the art of forming the granite into so many of its uses beautifully. Elberton Granite Association Welcomes

Newest Associate Member, Austin Powder

Let’s welcome the newest member of the Elberton Granite Association, Associate Member, AUSTIN POWDER. Austin Powder is a leader in the manufacturing, distribution, and application of industrial explosives for quarrying, surface mining and underground mining. They manufacture industrial explosives and accessories and provides technical and blasting services throughout the world.

The Southeast branch is located on Hartwell Highway in Elberton, Georgia. The Elberton location was established in January of 2022; however, it was not until around July of 2023 that all the structure and logistics were complete and ready for business. Ross Ellis is President of the Mid-Atlantic and Southeast, LLC. He oversees the local branch while Ed Harris holds the position of Sales Representative. Ed joined the company September of 2021.

The parent company began in 1833 when they began making black powder. Since that time the company developed and grew. They began serving the quarry and mining industries as they advanced with new, safer, and more reliable blasting products and technologies. They strive to provide the industry with the highest quality emulsions, electronic detonators and blasting expertise.

Austin Powder products and widely recognized support are commonly used in the natural stone industry to break granite or other natural stone from the earth. Without blasting, the natural stone industry would not be able to maintain the demand for monuments, crushed stone, or dimensional stone. The process of quarrying prior to the use of explosives was a slow and painstaking endeavor. For that reason, Austin Powder maintains staying on top of technology and safety guidelines. Austin Powder’s commitment to the industries begins with their commitment to safety. They employ certified blasters, state-of-the-art delivery systems, and the safest and highest quality products. They know that every quarry is unique. They strive to ensure that they help their customers choose just the right combination to ensure that production, quality, and safety are not sacrificed.

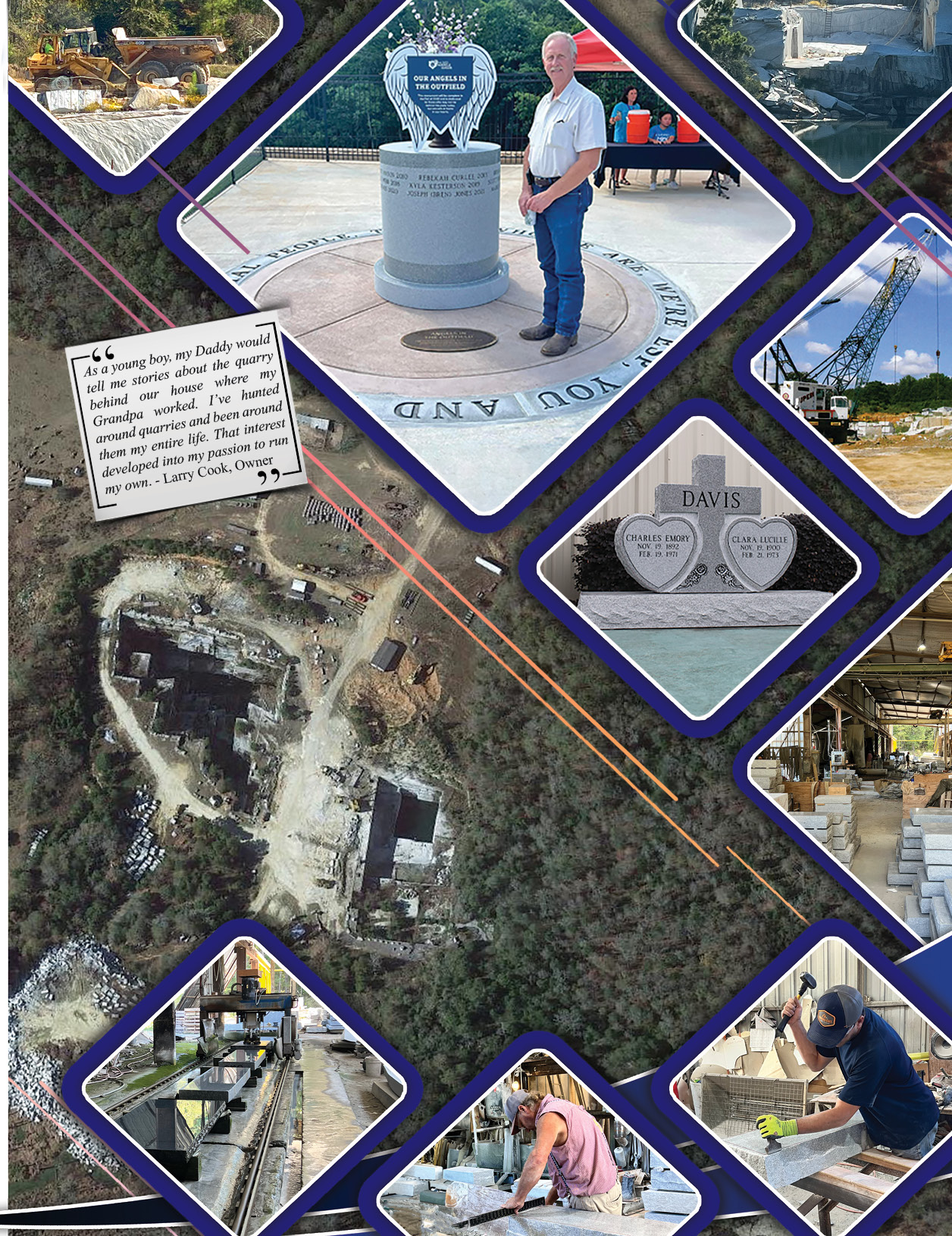

Owner, Larry Cook with daughters Amanda (left) and Delena (right)

BLUE RIBBON QUARRIES, INC. is this edition’s Member Spotlight. Blue Ribbon has been in operation since 1961 beginning under Walt McCannon’s leadership. The company was sold to Vince Fernandez and his father Manuel later. In the fall of 1999 Blue Ribbon became a member of the Elberton Granite Association. Today, Blue Ribbon is located off South Point Peter Road in Oglethorpe County and sits close to the Millstone Creek. Blue Ribbon quarries a medium blue granite with a fine grain and a millstone variegated select, which is now getting popular for monuments but has been used for a lot of countertop installations in the past.

Larry Cook purchased the company in 2006 from Mr. Fernandez and successfully began quarrying blocks and manufacturing slabs. The quarry was expanded in 2011 when two walls were moved back exposing new stone. Larry owns approximately 89 acres in the Millstone Creek area with about 29 acres of that being the quarry site.

In 2012, Larry purchased a firm formerly known as “Old Oak” and renamed it to Blue Ribbon Memorials under the umbrella of Blue Ribbon Quarries. He started selling cut rock, slabs, and finished monuments. Blue Ribbon has three block saws, a joint saw, and a slant saw for operation along with two polishing mills and a full-time hand polisher.

In 2017, Larry’s daughter, Amanda Stepp joined the company and began working in the office and as the overall general manager. She manages all operations of the quarries and the plant. “I only call Dad if there is a problem, I try to handle everything here on my own. I had to learn all about the granite process from start to finish and I am very proud and thankful to be here and watch our business grow.” stated Amanda.

In 2019, Larry purchased Briar Patch Quarries from Allen McGarity to add to the Blue Ribbon company. The Briar Patch site is a 114-acre tract with most of it being all stone. “It wasn’t an easy process opening up a new quarry” Larry stated. “New roads were built, power had to be installed, a small office was built, and new equipment was purchased along with all your blasting equipment and licenses... all through a pandemic.” The Briar Patch site is now operating and quarrying a medium blue granite very close to Blue Ribbon Quarries’ color. This quarry is located on Allgood Road in Oglethorpe County. Between both quarry sites, Blue Ribbon operates with three cranes, two off road dump trucks, a wire saw, automatic and handheld burners, line drills and lift hole drills. Both quarries are in operation and provide the shed with blocks along with many customers around the state including Elberton.

In 2022, Blue Ribbon began adding on to both sides of the manufacturing plant to make room for blocks brought in from the quarry and to allow more dock space. This also allowed the employees to load multiple trucks at one time.

Blue Ribbon supplies finished monuments, memorials, and coping, to customers all over the United States. However, their granite can also be purchased in block form, along with polished and unpolished slabs.

“Our future plans are to continue being a solid independently owned business who continues to supply blocks and cut rock to our customers.” stated Amanda. Larry retired from his main job in Athens earlier this year and plans to help the plant and quarry. He wants to build to having multiple crews at the quarries to supply more blocks to the community.

As a young boy, my Daddy would tell me stories about the quarry behind our house where my Grandpa worked. I’ve hunted around quarries and been around them my entire life. That interest developed into my passion to run my own. - Larry Cook, Owner

EGA Completes The

2023 Monument Retailer Course

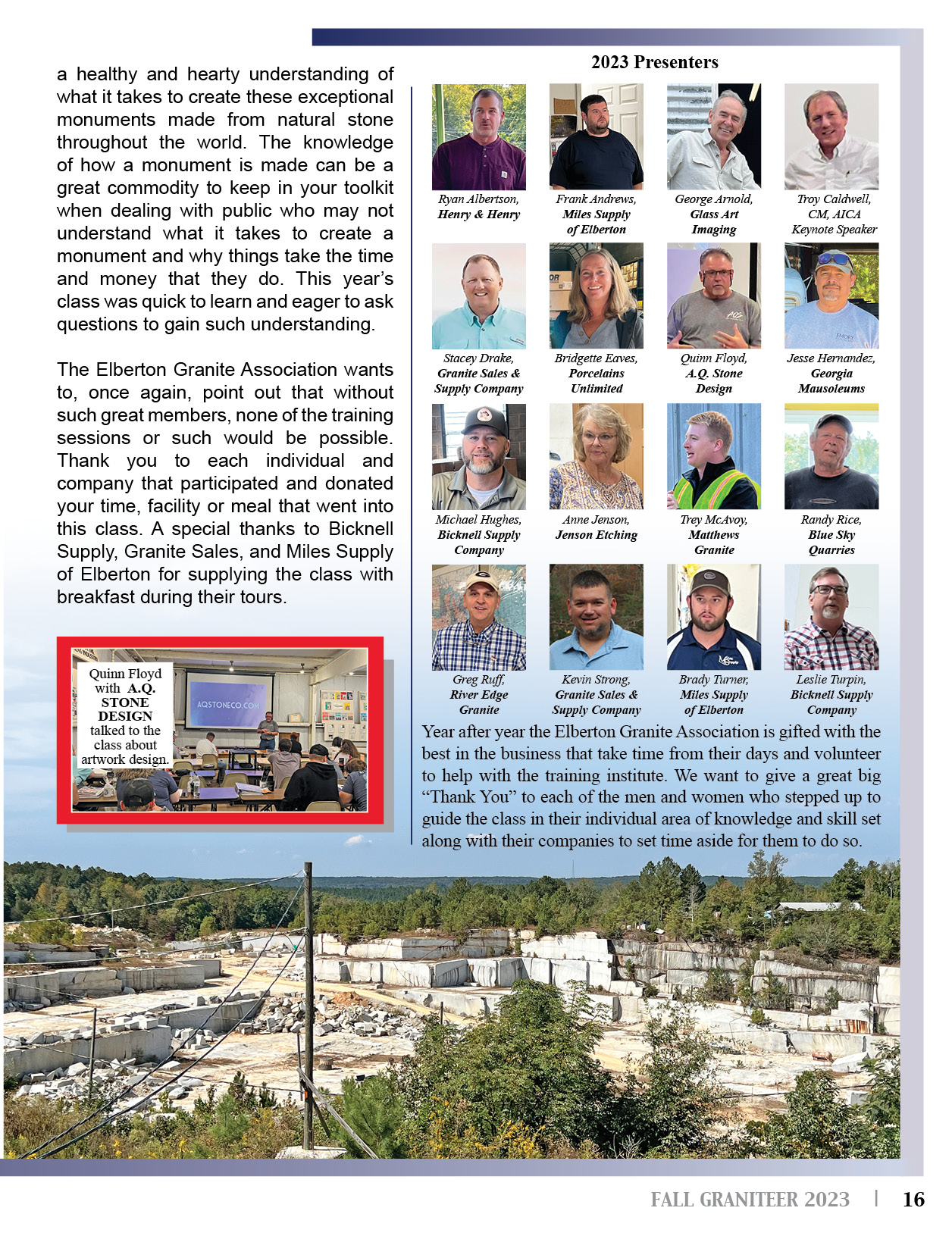

The class of 2023 brought with it a vast array of talent and walks of life. This class had everything from teenage business owners to retiree’s starting anew and employees yearning to learn more about their chosen profession. That thirst for knowledge was wildly encouraging and made for a great week of enlightenment. The class began with a visit to EGA’s quarry overlook platform where the attendees were able to witness several blocks lifted from the quarry via crane. From there, the class took trips to manufacturing plants where they were able to see just how those blocks were cut to slabs and broken out into monument sized pieces. They were able to walk through the plant where the life of the stone became more and more clear. They saw how the granite goes from quarry to cemetery with the many steps in between. The class was able to see the differences in creating pieces of a monument compared to pieces of a mausoleum. They were able to learn the different aspects that could be added to the monument after production such as etching, Glass Art and porcelains. As they walked through the manufacturing plants, they saw a block being cut into slabs using a diamond tipped gantry saw along with a diamond wire saw. After that, they came upon a machine polishing the slabs before moving down the line to be measured and broken out into smaller pieces, utilizing as much of the slab as possible for production. Once the class discussed the methods used in these steps, they moved on to witness finishing techniques such as hand polishing, stone carving, and sandblasting. The week was filled with many trips throughout town from quarries to plants and on to cemeteries and specialty shops that offer products or services. Classroom time was spread out throughout the week where Mentor and Instructor Troy Caldwell, CM, AICA, of Caldwell Monuments in Kokomo, Indiana spent time instructing the class of business techniques along with memorial creativity.

Each year, EGA puts this class on to help foster the growth of new people in the industry. The Association feels it is necessary to help people in the stone industry have a healthy and hearty understanding of what it takes to create these exceptional monuments made from natural stone throughout the world. The knowledge of how a monument is made can be a great commodity to keep in your toolkit when dealing with public who may not understand what it takes to create a monument and why things take the time and money that they do. This year’s class was quick to learn and eager to ask questions to gain such understanding.

The Elberton Granite Association wants to, once again, point out that without such great members, none of the training sessions or such would be possible. Thank you to each individual and company that participated and donated your time, facility or meal that went into this class. A special thanks to Bicknell Supply, Granite Sales, and Miles Supply of Elberton for supplying the class with breakfast during their tours. Year after year the Elberton Granite Association is gifted with the best in the business that take time from their days and volunteer to help with the training institute. We want to give a great big “Thank You” to each of the men and women who stepped up to guide the class in their individual area of knowledge and skill set along with their companies to set time aside for them to do so.

Leslie Turpin at BICKNELL SUPPLY discussed the different products available in the stone industry.

A group photo overlooking BLUE SKY QUARRIES was taken before touring the office and driving down into the quarry for a close up view.

Ryan Albertson with HENRY & HENRY along with Troy Caldwell demonstrated different unloading techniques used.

The class watched quarry workers prepare a block that had been broken away from its ledge at BLUE SKY QUARRIES. A group photo was taken at MILES SUPPLY OF ELBERTON to show the massive size of the gantry saw blades they re-tip for their customers.

George Arnold with GLASS ART discusses the timeless beauty of Glass Art images.

Greg Ruff with RIVER EDGE showed the class setting techniques.

Brian Jenson with JENSON ETCHING demonstrated painting etched stone.

Trey McAvoy with MATTHEWS GRANITE discussed slabs cut from granite blocks with the class.

Greg Ruff with RIVER EDGE went over different products and tips he has found helpful in setting stones.

Trey McAvoy walked the class through the production plant at MATTHEWS GRANITE discussing the different stages of production in creating monuments.

Brian Jenson discussed and answered questions about the variations of etching available with JENSON ETCHING.

A lesson on Monumask was given at BICKNELL SUPPLY.

Jesse Hernandez, Owner of member-firm, GEORGIA MAUSOLEUMS discussed the fabrication of different mausoleums with the class.

Bridgette Eaves with PORCELAINS UNLIMITED talked to the class about porcelain options.

A demonstration on recessing tiles was given at GRANITE SALES & SUPPLY.

Quinn Floyd with A.Q. STONE DESIGN talked to the class about artwork design.

Following the path that the most basic of monuments must go through to be delivered as a complete monument is extremely eye opening. A monument must first be taken from the Earth. This task is likely the most painstaking and risky. Care must be taken at all times to ensure safety. The stone is taken in block from and transferred via flatbed tractor trailer to the manufacturing company where the block is cut into slabs and processed. The slab is processed by finishing the face in the necessary polish or other finish and then measured and broken out into various shapes and sizes to fill orders. That stone is then fine-tuned with the many options of polishes and pitches before it is sent to sandblasting or etching and then trucked out to the retail customer or set directly into a cemetery. This timeline represents the most simple of processes. Monuments also require steps such as shape carving, stone cutting, laser etching, installing porcelains, Glass Art, and so much more before completion.

Ryan Albertson, Henry & Henry

Frank Andrews, Miles Supply of Elberton

George Arnold, Glass Art Imaging

Troy Caldwell,

CM, AICA Keynote Speaker

Stacey Drake, Granite Sales & Supply Company

Bridgette Eaves, Porcelains Unlimited

Quinn Floyd, A.Q. Stone Design

Jesse Hernandez, Georgia Mausoleums

Michael Hughes, Bicknell Supply Company

Anne Jenson, Jenson Etching

Trey McAvoy, Matthews Granite

Randy Rice, Blue Sky Quarries

Greg Ruff, River Edge Granite

Kevin Strong, Granite Sales & Supply Company

Brady Turner, Miles Supply of Elberton

Leslie Turpin, Bicknell Supply Company

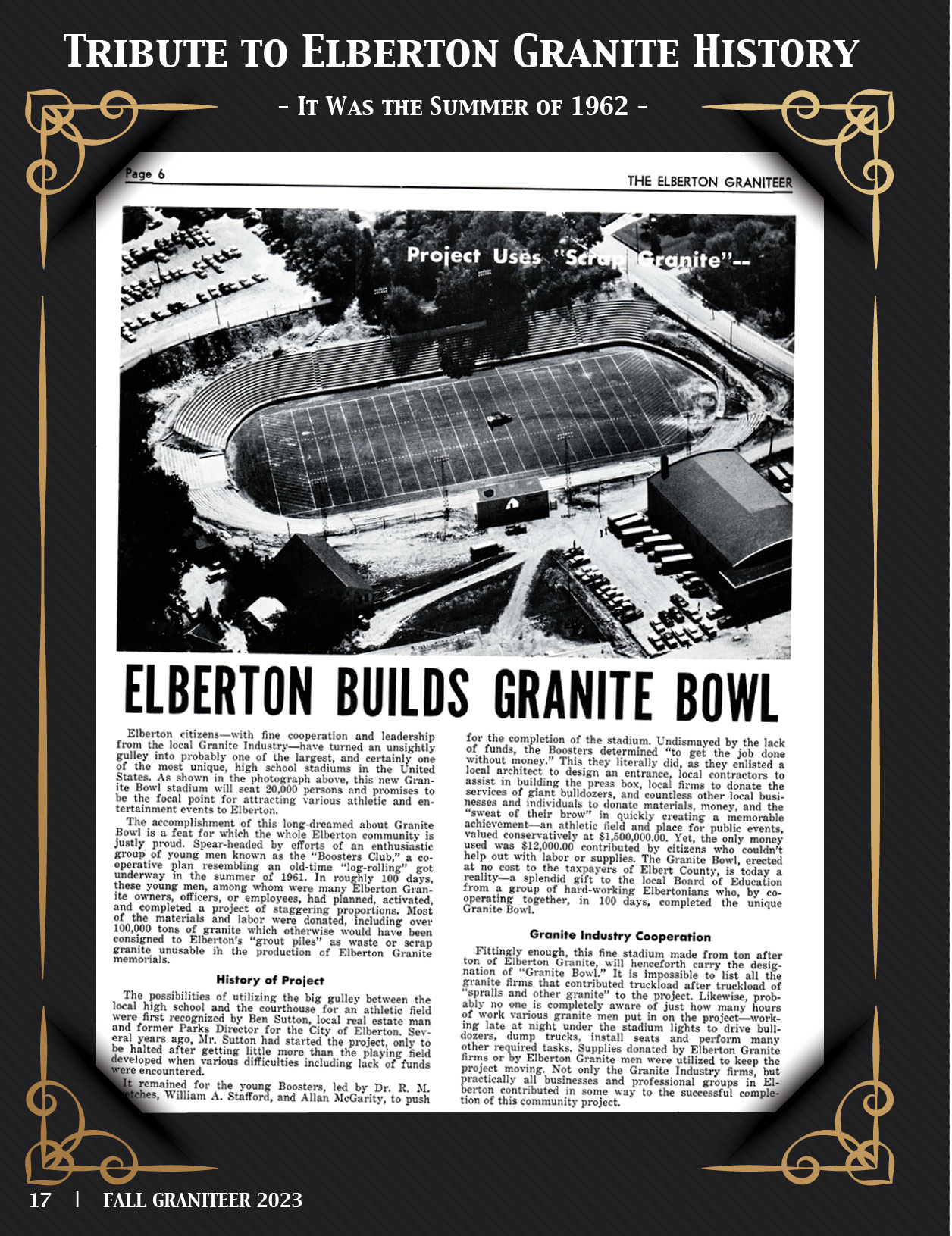

TRIBUTE TO ELBERTON GRANITE HISTORY – SUMMER OF 1962 ELBERTON BUILDS GRANITE BOWL

7th annual museum foundation golf tournament April 19, 2024, arrowhead pointe golf course

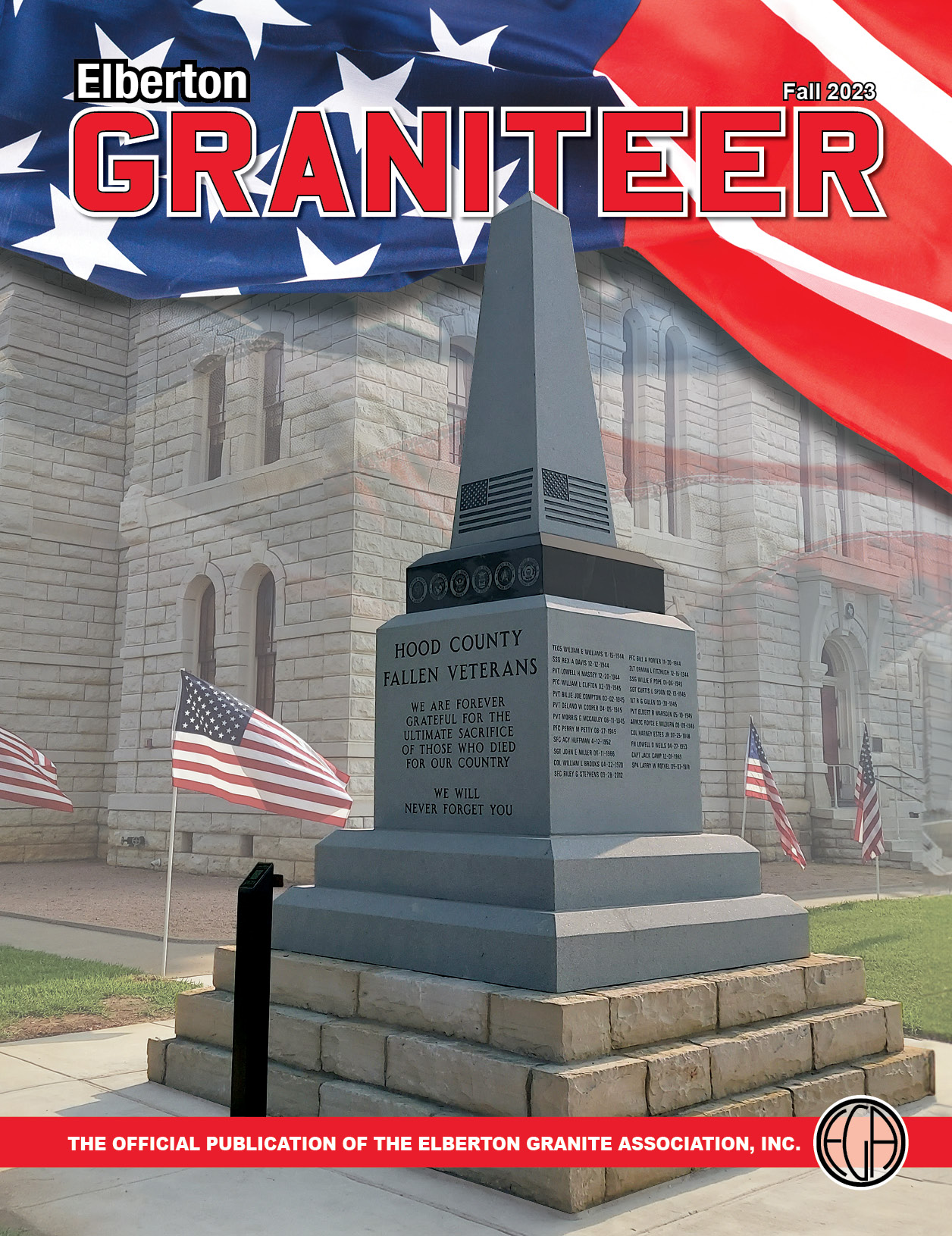

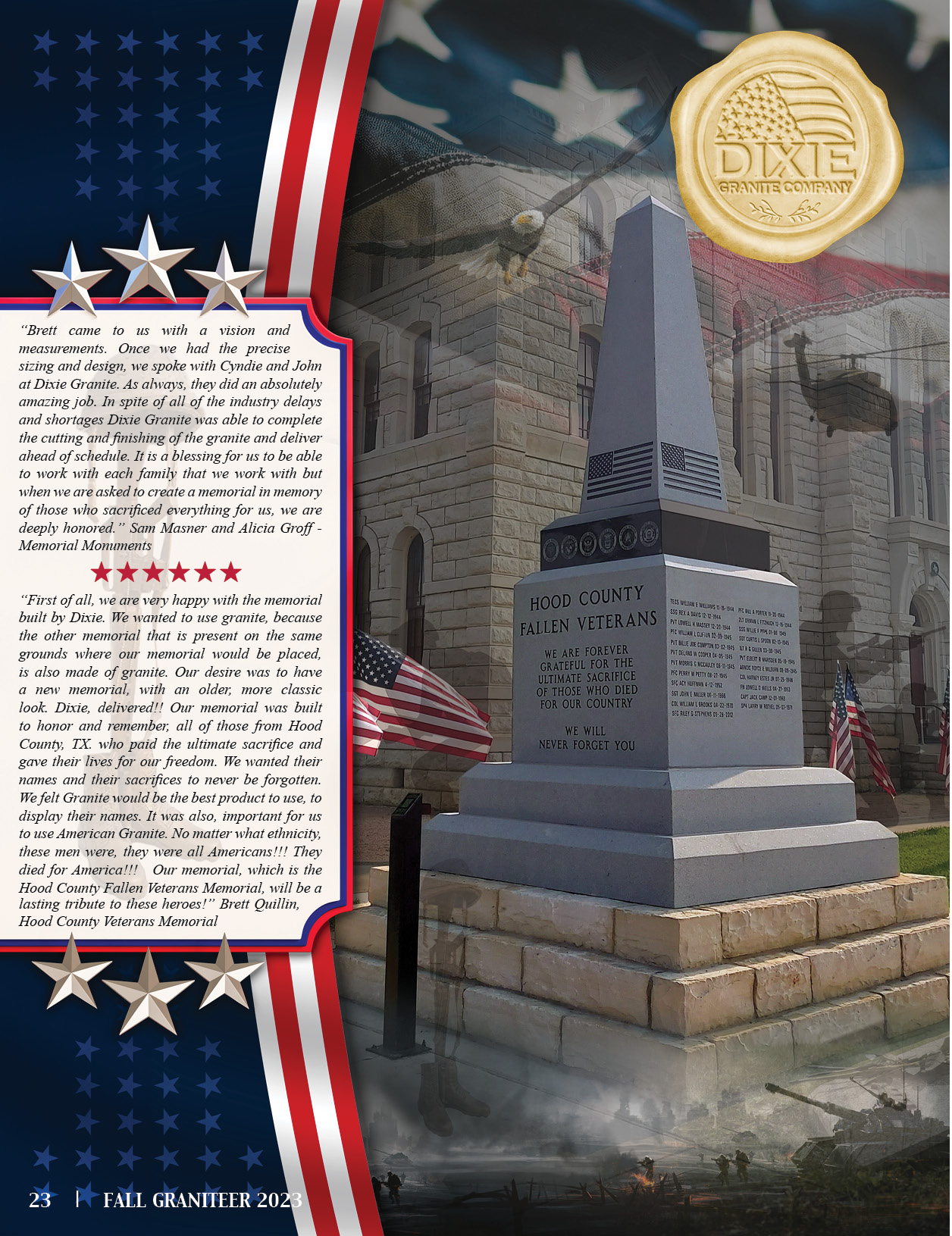

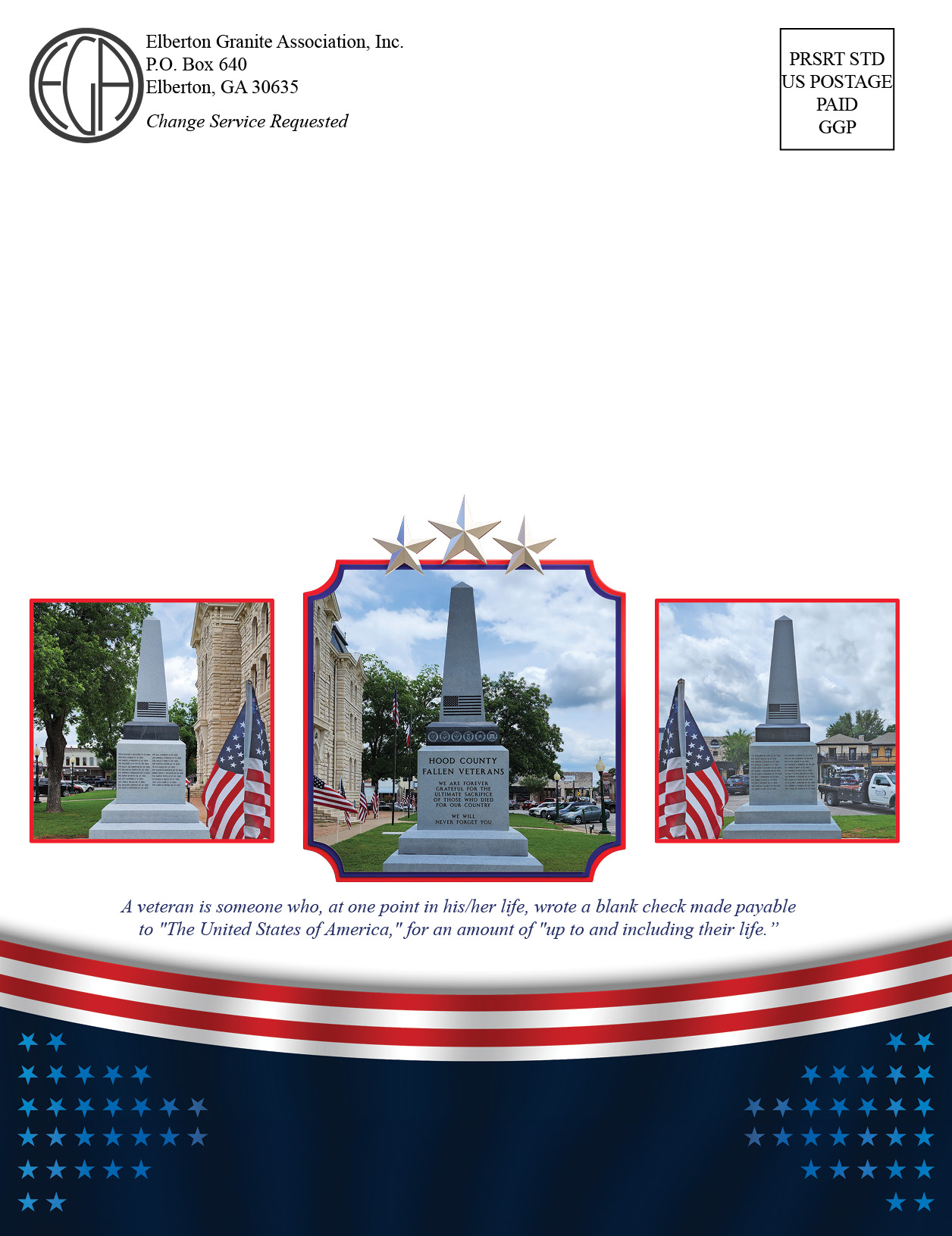

“Brett came to us with a vision and measurements. Once we had the precise sizing and design, we spoke with Cyndie and John at Dixie Granite. As always, they did an absolutely amazing job. In spite of all of the industry delays and shortages Dixie Granite was able to complete the cutting and finishing of the granite and deliver ahead of schedule. It is a blessing for us to be able to work with each family that we work with but when we are asked to create a memorial in memory of those who sacrificed everything for us, we are deeply honored.” Sam Masner and Alicia Groff - Memorial Monuments

“First of all, we are very happy with the memorial built by Dixie. We wanted to use granite, because the other memorial that is present on the same grounds where our memorial would be placed, is also made of granite. Our desire was to have a new memorial, with an older, more classic look. Dixie, delivered!! Our memorial was built to honor and remember, all of those from Hood County, TX. who paid the ultimate sacrifice and gave their lives for our freedom. We wanted their names and their sacrifices to never be forgotten. We felt Granite would be the best product to use, to display their names. It was also, important for us to use American Granite. No matter what ethnicity, these men were, they were all Americans!!! They died for America!!! Our memorial, which is the Hood County Fallen Veterans Memorial, will be a lasting tribute to these heroes!” Brett Quillin, Hood County Veterans Memorial

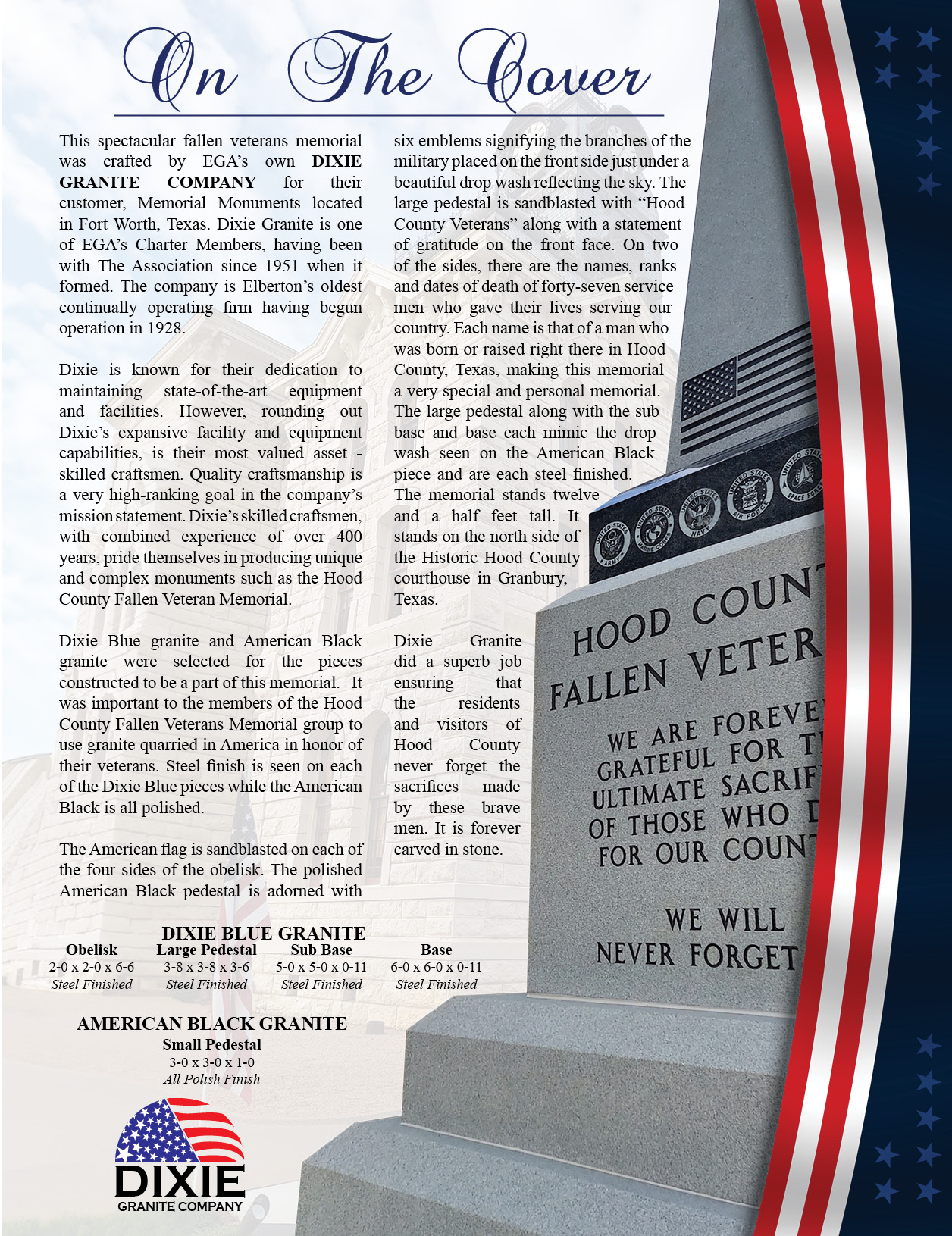

This spectacular fallen veterans memorial was crafted by EGA’s own DIXIE GRANITE COMPANY for their customer, Memorial Monuments located in Fort Worth, Texas. Dixie Granite is one of EGA’s Charter Members, having been with The Association since 1951 when it formed. The company is Elberton’s oldest continually operating firm having begun operation in 1928.

Dixie is known for their dedication to maintaining state-of-the-art equipment and facilities. However, rounding out Dixie’s expansive facility and equipment capabilities, is their most valued asset - skilled craftsmen. Quality craftsmanship is a very high-ranking goal in the company’s mission statement. Dixie’s skilled craftsmen, with combined experience of over 400 years, pride themselves in producing unique and complex monuments such as the Hood County Fallen Veteran Memorial.

Dixie Blue granite and American Black granite were selected for the pieces constructed to be a part of this memorial. It was important to the members of the Hood County Fallen Veterans Memorial group to use granite quarried in America in honor of their veterans. Steel finish is seen on each of the Dixie Blue pieces while the American Black is all polished.

The American flag is sandblasted on each of the four sides of the obelisk. The polished American Black pedestal is adorned with six emblems signifying the branches of the military placed on the front side just under a beautiful drop wash reflecting the sky. The large pedestal is sandblasted with “Hood County Veterans” along with a statement of gratitude on the front face. On two of the sides, there are the names, ranks and dates of death of forty-seven service men who gave their lives serving our country. Each name is that of a man who was born or raised right there in Hood County, Texas, making this memorial a very special and personal memorial. The large pedestal along with the sub base and base each mimic the drop wash seen on the American Black piece and are each steel finished. The memorial stands twelve and a half feet tall. It stands on the north side of the Historic Hood County courthouse in Granbury, Texas.

Dixie Granite did a superb job ensuring that the residents and visitors of Hood County never forget the sacrifices made by these brave men. It is forever carved in stone.

SOUTHERN GRANITE COMPANY and JENSON ETCHING teamed up to complete this tractor shaped monument for Caldwell Monuments in Kokomo, Indiana. Excellence can always be expected when EGA members collaborate to accomplish something. Southern Granite Company utilized the latest technology to take a standard jet black stone and transform it to replicate the outline of a tractor. A mirror shine was polished onto the surface and the stone was sent to Jenson Etching. At Jenson Etching, the team began the task of measuring the stone, adjusting art, and programming their machinery to fit the image of the tractor seamlessly along all the curves and edges. Detail and quality are abundant on this monument from fabrication to completion. The memorial can be found at Maple Lawn Cemetery in Flora, Indiana.

This spectacular memorial, made with Missouri Red granite was crafted by KEYSTONE MEMORIALS for Washington Monument Company, Inc. located in Washington, Missouri. The tablet features a relief carved Odd Fellows emblem within a circular recessed niche. The shape of the top of the stone mimics the curve of the relief carving flowing into a check and exaggerated round. Below the round is a bead before settling into a straight end. The top and ends are all steel finish.

The top of the base is polished to a shine while the ends are each rock pitched. The Houseman memorial can be found in the Wildey Odd Fellows Cemetery in Washington, Missouri.

EAGLE GRANITE, a division of MATTHEWS GRANITE mastered crafting this pre-need mausoleum for local Paul family. The Paul family has been trusted leaders in the Elberton granite industry for decades and they continue to share their talents through Eagle Granite. The mausoleum is crafted from Silver Cloud granite quarried from fellow EGA member BROAD RIVER QUARRIES in Lithonia, Georgia.

This outstanding six-crypt mausoleum features two turned and fluted Tuscan style columns. One on each side of the bronze doorway creating an elegant look on the portico. In addition to the six-crypt capacity, it also was built with fourteen niches to hold cremains. The gable roof features a center keystone uniting the left and right side. The edges of the roof are adorned with a beautiful scotia that encompasses the pediment. Within the pediment is a recessed panel with the raised letters spelling the family name. Under the roof and pediment is a band of molding around the entire mausoleum with same beautiful scotia completing the bottom of the triangle shape of the roof.

This flat marker bears the vibrant and unique color images of GLASS ART IMAGING. Glass Art® applied to any stone transforms the memorial to a work of art that allows colorful personalization that will stand the test of time. The colors in Glass Art® are infused into the granite with lasers to create a durable, and long-lasting image that is guaranteed not to will not to chip, peel, or fade. Glass Art® can be applied to virtually any color of stone.

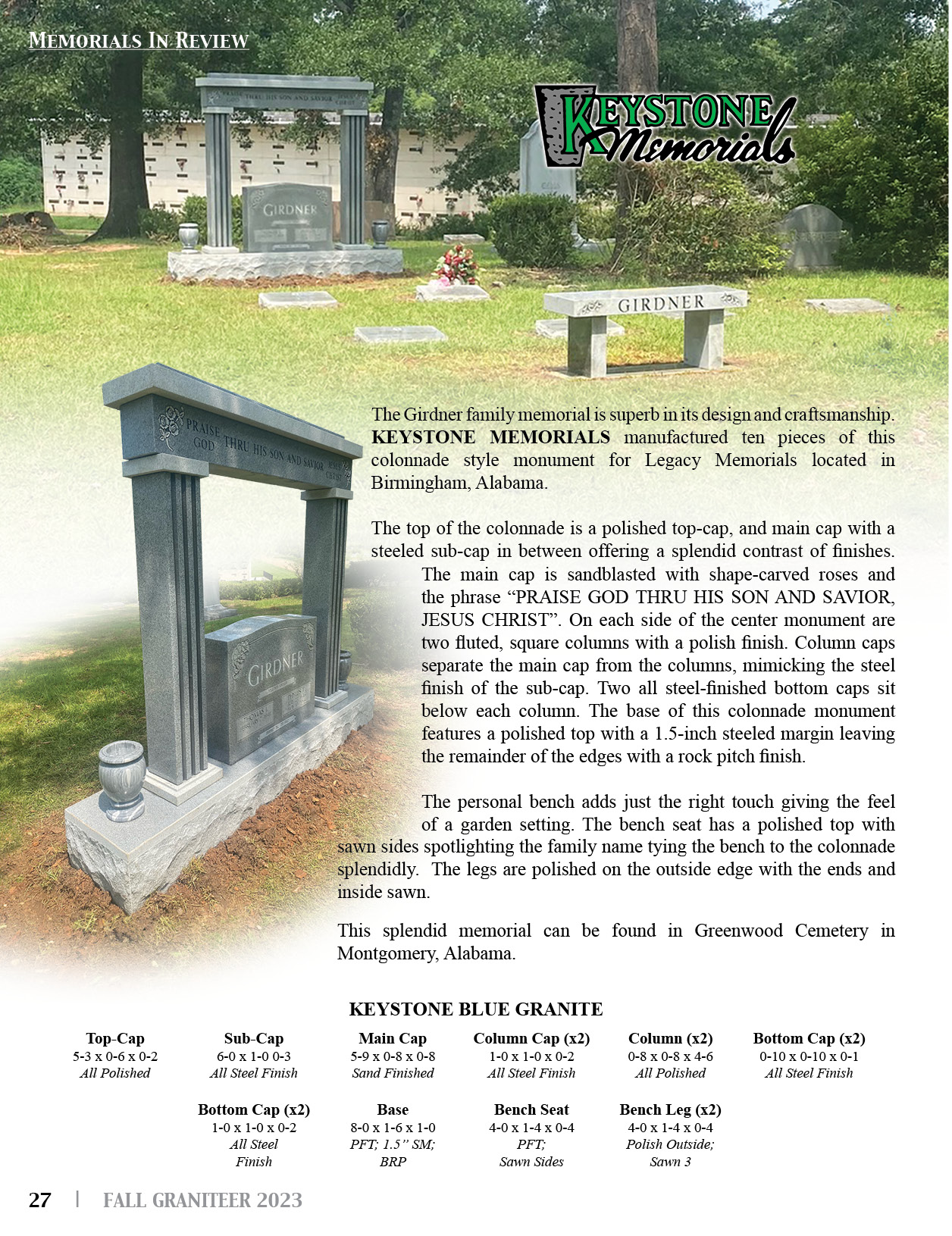

The Girdner family memorial is superb in its design and craftsmanship. KEYSTONE MEMORIALS manufactured ten pieces of this colonnade style monument for Legacy Memorials located in Birmingham, Alabama.

The top of the colonnade is a polished top-cap, and main cap with a steeled sub-cap in between offering a splendid contrast of finishes. The main cap is sandblasted with shape-carved roses and the phrase “PRAISE GOD THRU HIS SON AND SAVIOR, JESUS CHRIST”. On each side of the center monument are two fluted, square columns with a polish finish. Column caps separate the main cap from the columns, mimicking the steel finish of the sub-cap. Two all steel-finished bottom caps sit below each column. The base of this colonnade monument features a polished top with a 1.5-inch steeled margin leaving the remainder of the edges with a rock pitch finish.

The personal bench adds just the right touch giving the feel of a garden setting. The bench seat has a polished top with sawn sides spotlighting the family name tying the bench to the colonnade splendidly. The legs are polished on the outside edge with the ends and inside sawn.

This splendid memorial can be found in Greenwood Cemetery in Montgomery, Alabama.

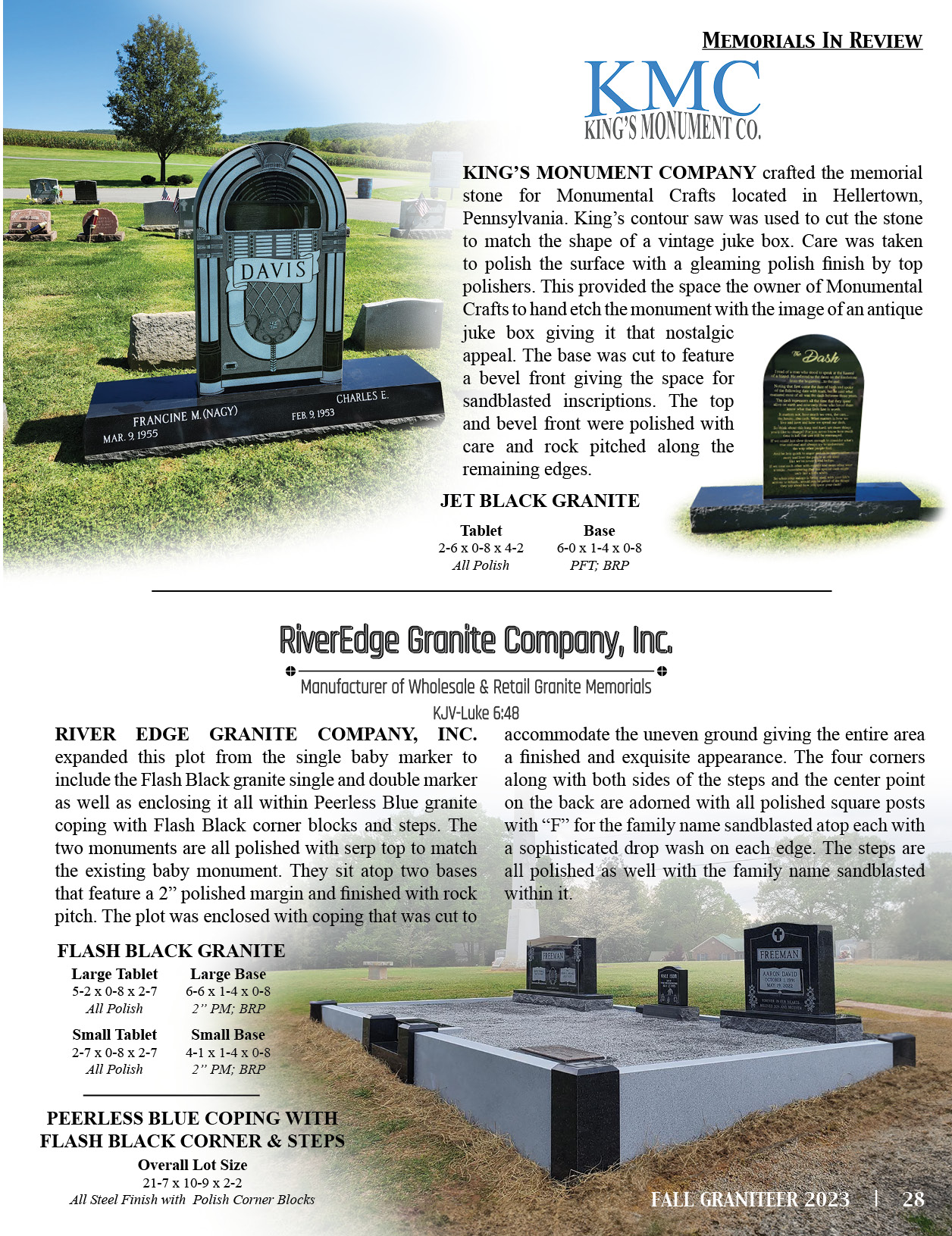

KING’S MONUMENT COMPANY crafted the memorial stone for Monumental Crafts located in Hellertown, Pennsylvania. King’s contour saw was used to cut the stone to match the shape of a vintage juke box. Care was taken to polish the surface with a gleaming polish finish by top polishers. This provided the space the owner of Monumental Crafts to hand etch the monument with the image of an antique juke box giving it that nostalgic appeal. The base was cut to feature a bevel front giving the space for sandblasted inscriptions. The top and bevel front were polished with care and rock pitched along the remaining edges.

RIVER EDGE GRANITE COMPANY, INC. expanded this plot from the single baby marker to include the Flash Black granite single and double marker as well as enclosing it all within Peerless Blue granite coping with Flash Black corner blocks and steps. The two monuments are all polished with serp top to match the existing baby monument. They sit atop two bases that feature a 2” polished margin and finished with rock pitch. The plot was enclosed with coping that was cut to accommodate the uneven ground giving the entire area a finished and exquisite appearance. The four corners along with both sides of the steps and the center point on the back are adorned with all polished square posts with “F” for the family name sandblasted atop each with a sophisticated drop wash on each edge. The steps are all polished as well with the family name sandblasted within it.

MATTHEWS GRANITE has proven again, the level of craftsmanship and quality that can be expected when placing your trust in them. This beautifully crafted monument was fabricated for Toler Monuments in Wise, North Carolina. It can be found in Oakdale Cemetery in Washington, North Carolina. The cap is cut to form a ridge top with a small bevel wash on the bottom side. It is finished off with a check that leads to an all polished sub cap that features 3-inch raised letters in a sunken panel on the front and back. The two square columns display polished, raised crosses on the front of each within sunken panels. The first sub base features a frosted v-line panel with sunk lettering. It is all polished with a beautiful scotia transitioning to the second sub base. This sub base along with the base are polished on the top with the edges rock pitched.

Sitting in front of the monument rests a matching bench. The bench top mimics the same raised family name sitting within a sunken panel. The bench support is cut with scotia ends that match the sub base on the monument. The base features a polished top with rock pitched edges.

Member-Firm, DIXIE GRANITE COMPANY manufactured this monument to form the corner post at the beginning of Trail Creek Bridge on the newly created Fire Fly Trail in Athens, Georgia. The monument weighs roughly 7,500 lbs. and stands 6-ft. 7-in. tall. The top is carved with a 7-in. dropwash off of a flat top. Dixie used their exclusive Dixie Blue granite to create this monument.

Dixie Granite Company has been creating quality monuments since 1928, making it the oldest continually operating firm in Elberton. They have proven time and again that the monuments coming from their facility can be trusted to have the greatest of craftsmanship.

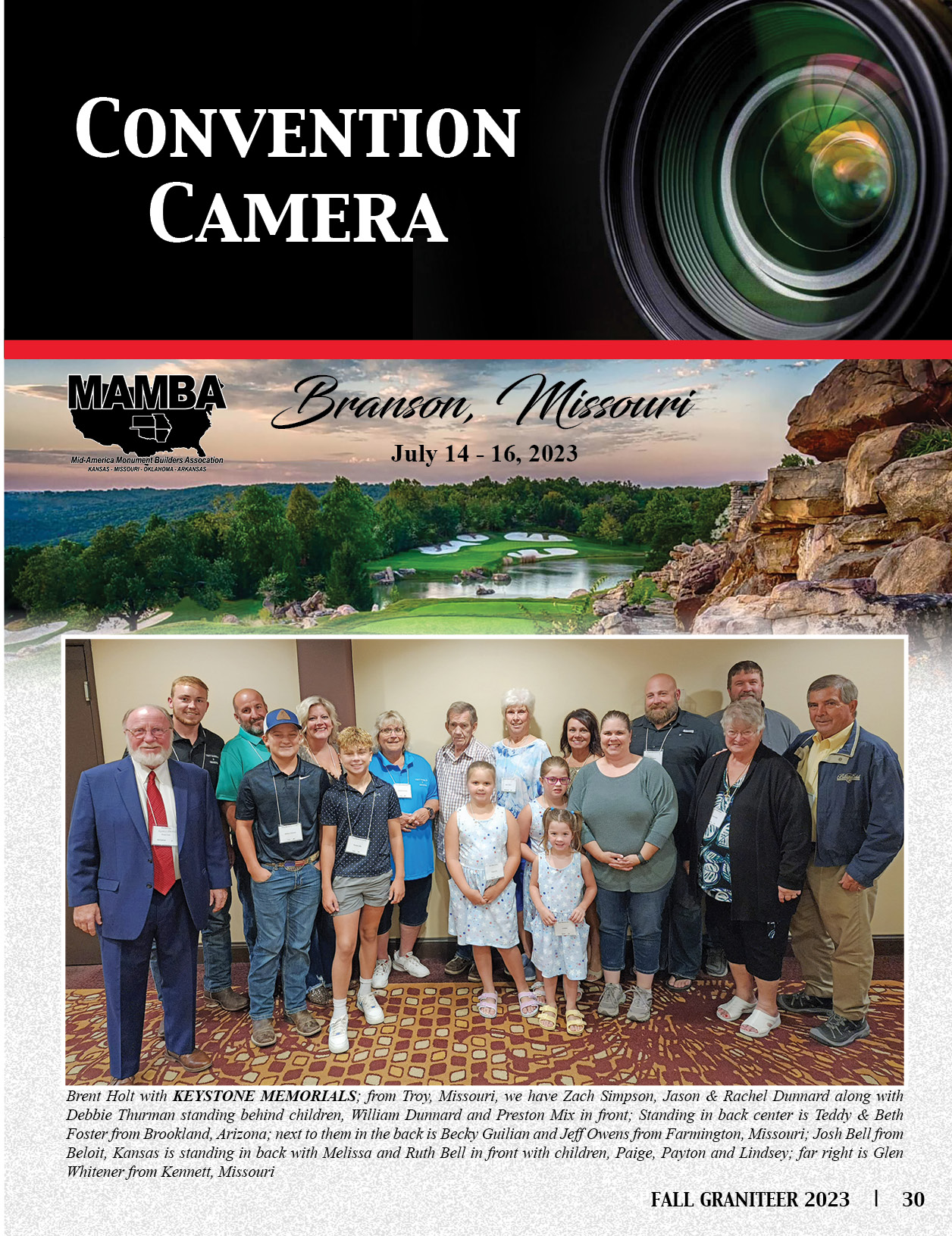

Brent Holt with KEYSTONE MEMORIALS; from Troy, Missouri, we have Zach Simpson, Jason & Rachel Dunnard along with Debbie Thurman standing behind children, William Dunnard and Preston Mix in front; Standing in back center is Teddy & Beth Foster from Brookland, Arizona; next to them in the back is Becky Guilian and Jeff Owens from Farmington, Missouri; Josh Bell from Beloit, Kansas is standing in back with Melissa and Ruth Bell in front with children, Paige, Payton and Lindsey; far right is Glen Whitener from Kennett, Missouri

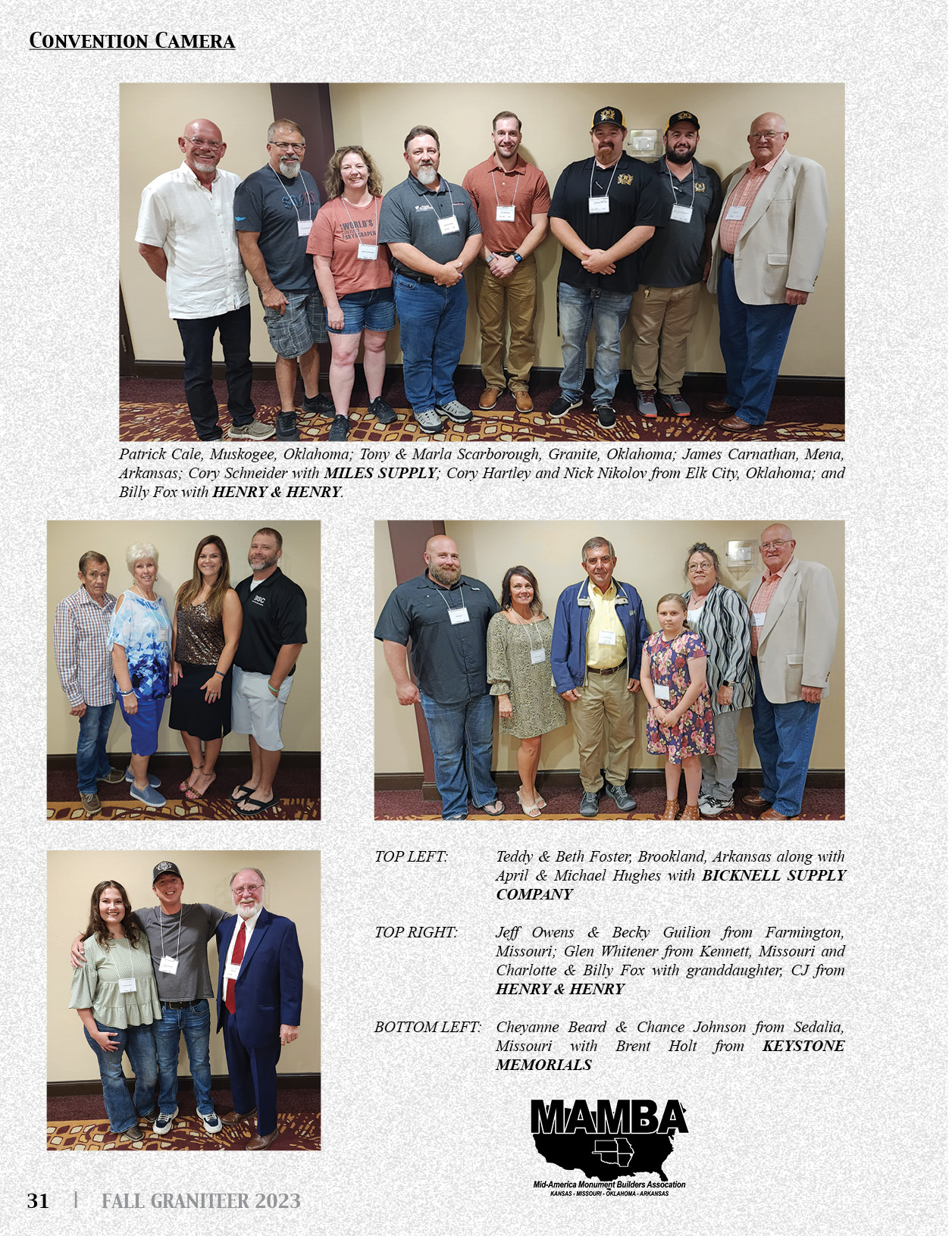

Patrick Cale, Muskogee, Oklahoma; Tony & Marla Scarborough, Granite, Oklahoma; James Carnathan, Mena, Arkansas; Cory Schneider with MILES SUPPLY; Cory Hartley and Nick Nikolov from Elk City, Oklahoma; and Billy Fox with HENRY & HENRY.

OP LEFT: Teddy & Beth Foster, Brookland, Arkansas along with April & Michael Hughes with BICKNELL SUPPLY COMPANY

TOP RIGHT: Jeff Owens & Becky Guilion from Farmington, Missouri; Glen Whitener from Kennett, Missouri and Charlotte & Billy Fox with granddaughter, CJ from HENRY & HENRY

BOTTOM LEFT: Cheyanne Beard & Chance Johnson from Sedalia, Missouri with Brent Holt from KEYSTONE MEMORIALS

Scott Streetman, MATTHEWS GRANITE; Jonathan Lasky, New Orleans, LA; and Trey McAvoy, MATTHEWS GRANITE

Sanford Butler, MATTHEWS GRANITE and Lenny Vargus, Miami, FL

Lilliam Machade, Washington, DC; Trey McAvoy & Scott Streetman, MATTHEWS GRANITE; and Lauri Brown, Washington, DC

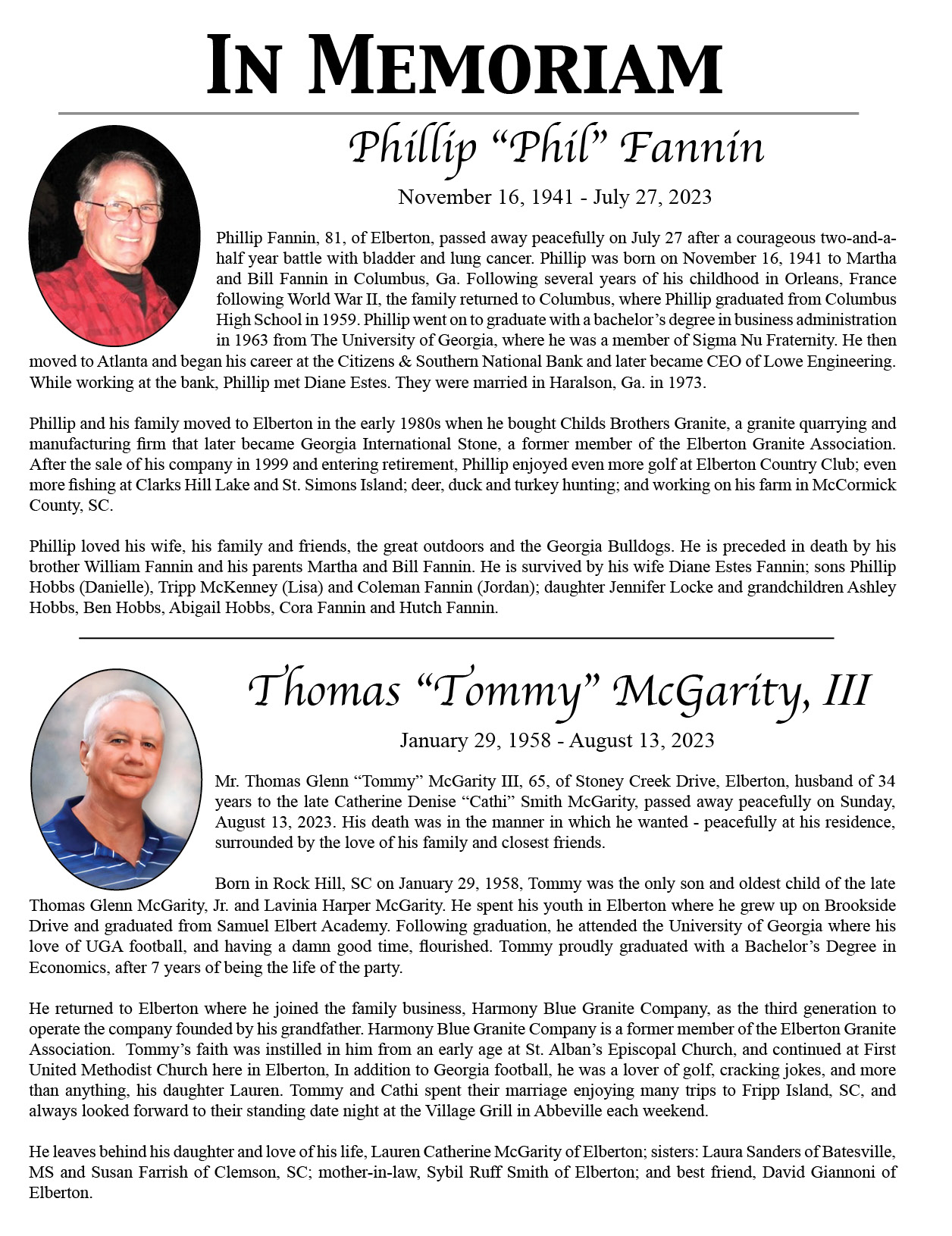

Phillip Fannin, 81, of Elberton, passed away peacefully on July 27 after a courageous two-and-a-half year battle with bladder and lung cancer. Phillip was born on November 16, 1941 to Martha and Bill Fannin in Columbus, Ga. Following several years of his childhood in Orleans, France following World War II, the family returned to Columbus, where Phillip graduated from Columbus High School in 1959. Phillip went on to graduate with a bachelor’s degree in business administration in 1963 from The University of Georgia, where he was a member of Sigma Nu Fraternity. He then moved to Atlanta and began his career at the Citizens & Southern National Bank and later became CEO of Lowe Engineering. While working at the bank, Phillip met Diane Estes. They were married in Haralson, Ga. in 1973.

Phillip and his family moved to Elberton in the early 1980s when he bought Childs Brothers Granite, a granite quarrying and manufacturing firm that later became Georgia International Stone, a former member of the Elberton Granite Association. After the sale of his company in 1999 and entering retirement, Phillip enjoyed even more golf at Elberton Country Club; even more fishing at Clarks Hill Lake and St. Simons Island; deer, duck and turkey hunting; and working on his farm in McCormick County, SC.

Phillip loved his wife, his family and friends, the great outdoors and the Georgia Bulldogs. He is preceded in death by his brother William Fannin and his parents Martha and Bill Fannin. He is survived by his wife Diane Estes Fannin; sons Phillip Hobbs (Danielle), Tripp McKenney (Lisa) and Coleman Fannin (Jordan); daughter Jennifer Locke and grandchildren Ashley Hobbs, Ben Hobbs, Abigail Hobbs, Cora Fannin and Hutch Fannin.

Mr. Thomas Glenn “Tommy” McGarity III, 65, of Stoney Creek Drive, Elberton, husband of 34 years to the late Catherine Denise “Cathi” Smith McGarity, passed away peacefully on Sunday, August 13, 2023. His death was in the manner in which he wanted - peacefully at his residence, surrounded by the love of his family and closest friends.

Born in Rock Hill, SC on January 29, 1958, Tommy was the only son and oldest child of the late Thomas Glenn McGarity, Jr. and Lavinia Harper McGarity. He spent his youth in Elberton where he grew up on Brookside Drive and graduated from Samuel Elbert Academy. Following graduation, he attended the University of Georgia where his love of UGA football, and having a damn good time, flourished. Tommy proudly graduated with a Bachelor’s Degree in Economics, after 7 years of being the life of the party.

He returned to Elberton where he joined the family business, Harmony Blue Granite Company, as the third generation to operate the company founded by his grandfather. Harmony Blue Granite Company is a former member of the Elberton Granite Association. Tommy’s faith was instilled in him from an early age at St. Alban’s Episcopal Church, and continued at First United Methodist Church here in Elberton, In addition to Georgia football, he was a lover of golf, cracking jokes, and more than anything, his daughter Lauren. Tommy and Cathi spent their marriage enjoying many trips to Fripp Island, SC, and always looked forward to their standing date night at the Village Grill in Abbeville each weekend.

He leaves behind his daughter and love of his life, Lauren Catherine McGarity of Elberton; sisters: Laura Sanders of Batesville, MS and Susan Farrish of Clemson, SC; mother-in-law, Sybil Ruff Smith of Elberton; and best friend, David Giannoni of Elberton.

Date:

FALL 2023

Year:

2 023

Season:

FALL

Description:

GRANITEER FALL 2O23